Water Solution: Standard Seawater Desalination

YS-10T/DAY Seawater Desalination RO Machine

| 1. Design lnstruction: | |||||

|

1.1 voltage: 3P AC380 50HZ, 4.6kw. 1.2 Water production:10T per day. 1.3 With high and low pressure protection, overload protection, liquid level protection, etc. 1.4 Can monitorthe produced waterqua lity online in realtime via conductivity. 1.5 The electricalcontrol adopts dualcontrolunits, one with PLC(automaticcontrol) + HMl (touch screen), and theother with relay, so that the equipment canrun smoothlyeven in case ofemergencies, and the reliability of the equipmentis high. 1.6 With automatic flushingto prolong the service life of RO membrane. |

|||||

| 2. Main configurationlist: | |||||

| No. | Name | Specification | Brand | Quantity | Remark |

| 1 | Pretreatment system | ||||

| 1.1 | Raw water pump |

Material: stainless steels S316L, AC380V 50Hz |

CNP | 1Set | |

| 1.2 | Quartz Sand Filter | ||||

| Filter Tank | YB-1035 | 1Pcs | With upper and lower water distributor | ||

| Filter valve | F56F | 1Pcs | |||

| Quartz Sand | 1-8mm | 25OKG | |||

| 1.3 | Precision filter | ||||

| Filter | 20 inch with vent valve, 5um | 2Set | |||

| 1.4 | Dosing pump | SEKO | 1Set | ||

| Dosing box | 1Pcs | ||||

| 2 | Ro host machine | ||||

| 2.1 | RO membrane shell | FRP material, 4040* 1,1000, PSl, water contact material of the end cover, dual-phase steel 2507 | 3Pcs | ||

| Ro membrane | SW4040, Dow, USA | DOW | 3Pcs | ||

| 2.2 | High pressure pump | Brass material, 1000PSI | AR | 1Pcs | |

| Motor | 3P AC380V 50HZ | 1Pcs | |||

| 3 | Instruments and apparatus | ||||

| 3.1 | High and low voltage protection probe | 1batch | |||

| 3.2 | Panel pressure gauge | SS316 oil injection shock resistance | 1batch | ||

| 3.3 | Flowmeter | 1batch | |||

| 3.4 | Conductivity meter | 0-2000ppm | 1Pcs | ||

| 3.5 | High pressure elettric slow opening flushing valve | SS316 4/8" 1000PSI | 1Pcs | ||

| 4 | Valves and Fittings | ||||

| 4.1 | High pressure regulating valve | SS316L 4/8" external thread 1000PSI | 1Pcs | ||

| 4.2 | Low pressure pipe fttings | UPVC, DN15-25 | 1batch | ||

| 4.3 | High pressure pipe | High pressure resin &316L, 4/8" 1000PSI | 1batch | ||

| 4.4 | High pressure connector | 1000PSI SS316L | 1batch | ||

| 5 | Electronic control | ||||

| 5.1 | PLC | DVP32 | 1Set | ||

| 5.2 | HMI | 7 inch | 1Set | ||

| 5.3 | Electric control box | Carbon steel paint | 1Set | ||

| 5.3 | Other electrical components | Chint or Etong | 1batch | ||

| 6 | Frame and packing | ||||

| 6.1 | Frame | SS304 stainless steel | 1Pcs | ||

| 6.2 | Packing | Wooden box | 1Pcs | ||

YS-20T/DAY Seawater Desalination RO Machine

| 1. Design lnstruction: | ||||||

|

1) Inlet water qulity: No pluted seawater, Turbidity≤5NTU, TDS≤35000PPM; 2) Prodution water quality: TDS≤700PPM; 3) System inlet water: connection port DN32, 3.0m3/h; 4) Production water flow rate: connection DN15, 1.0 m3/h; 5) Recovery rate: 33%; 6) Power: 3phase, 380V50Hz, 9.0kw; Double control system for easy operation. |

||||||

| 2. Main configuration list | ||||||

| No. | Name | Model and Specification | Brand | Unit | Quantity | Remark |

| 1 | Pretreatment | |||||

| 1.1 | Raw water pump |

0.75KW/380V/50H2/5S316L material |

CNP | Psc | 1 | |

| 1.2 | Mult-media filter | Set | ||||

| Filter Tank | FRP/1865 | Set | 1 | Indluding water distributors | ||

| Multiway fiter valve | GL10-2 | JY | Set | 1 | ||

| Filtration media | Quartz sand | KG | 300 | |||

| 1.3 | Dosing System | Set | 1 | |||

| Dosing tank | PE/60L | Pcs | 1 | |||

| Dosing pump | Newdsoe | Set | 1 | |||

| 1.4 | Cartridge fiter | 1.5inch filter housing, big blue, 20inch | Set | 2 | ||

| Fiter bag | PP pleated, 115*506 5um | Pcs | 2 | |||

| 2 | RO host | |||||

| 2.1 | High pressure pump head | 50LPM, 70bar, S5316L | AR | Pcs | 1 | |

| Motor | 7.5-4-380 | Pcs | 1 | |||

| 2.2 | FRP vessel | FRP/1000ps/4040*2 | Pcs | 3 | Side port | |

| 2.3 | RO membrane | 4" seawater membrane | Vontron | Pcs | 6 | |

| 2.4 | Safty valve | Brass, 60BAR | PINFL | Pcs | 1 | |

| 2.5 | Buffer | 55316L, 1000psi, 0.75L | Pcs | 1 | ||

| 3 | Flushing system | |||||

| 3.1 | Flushing water tank | PE/100L | Pcs | 1 | Customer provide | |

| 3.2 | Flushing pump | 0.55KW/380V/50H2/55304 | CNP | Pcs | 1 | |

| 3.3 | Flushing cartridge filter | 15in flter housing big blue, 20in | Set | 1 | ||

| large flux flter cartridge | PP pleated 115*506 5um | Pcs | 1 | |||

| 4 | Instruments | |||||

| 4.1 | Conductvity meter | Water production 3320 | create | Pcs | 1 | |

| 4.2 | Raw wawter flowmeter | Pipeline type/0.6-6m2/h | Yuanda | Pcs | 1 | |

| 4.3 | Water production flowmeter | Pipeline type/0.6-6m2/h | Yuanda | Pcs | 1 | |

| 4.4 | Concentrated water flowmeter | Pipeline type/0.6-6m/h | Yuanda | Pcs | 1 | |

| 4.5 | Fushing flowmeter | Plpeline type/10-10m/h | Yuanda | Pcs | 1 | |

| 4.6 | Pressure guge | 0.7/10.0mpa | KTYB | Pcs | 4 | |

| 4.7 | Low pressure switch | 1bar, 55316 | SICH | Pcs | 1 | |

| 4.8 | High pressure switch | 60bar, 55316 | SICH | Pcs | 1 | |

| 5 | Valves and pipe fittings | |||||

| 5.1 | Low pressure pipe |

UPVC, gray, 1.6MPa, DN15-DN40 | batch | 1 | ||

| 5.2 | High pressure pipe | 1000P51, 55316L and high pressure resin | batch | 1 | ||

| 5.3 | High pressure stop valve | DN20, 5S316L,1000P51 | Pcs | 1 | ||

| 5.4 | Flushing eletric valve |

DN20, 1000psi, 5S316L | MD | Pcs | 1 | |

| 5.5 | Flushing water refil valve |

solenoid valve, DN15 | Pcs | 1 | ||

| 6 | Electric Control |

|||||

| 6.1 | Electric cabinet |

Carbon steel (baking paint), size: 600*500* 250mm | Set | 1 | ||

| 6.2 | PLC |

DVP-32 | Delta | Pcs | 1 | |

| 6.3 | HMI | 10" | WEINVIEW | Pcs | 1 | |

| 6.4 | Frequency converter | C2000 11KW | Delta | Pcs | 1 | |

| 6.5 | Cooling fan | 120* 120 with dust screen | Set | 2 | ||

| 6.6 | Others | |||||

| 7 | Frame and Packing | |||||

| 7.1 | RO host frame | Carbon steel, Slze: 25*0.9*1.7M | Set | 1 | ||

| 7.2 | Pretreatment system | No frame, set on floor | Set | 1 | ||

| 7.3 | Packing | Plywoodcase for export | Set | 1 | ||

Features overview:

1. Auto working by pressing one key, easy and comvenient to operate. .

2. Dual control system, PLC touch screen control + relay control. Efectively solve the problem that the control system fails to use.

3. The machine sets up high and low vllage protedion to prevent the machine from break downing.

4. Device fault alam and indicafion is convenient for ientiying the causes and maintenance quidkly.

5. Alkinds of flow and pressure testng instruments, monitoring the device operatfig state at any time.

6. Online condutity meter, monitoringthe output water quality at any time.

7. Fully plishedstainless steel frame, safe and fastness, elegant appearanoe.

8. Famous brand high qulty seawater RO membrane, salt removing ralte can reachupto 99.8%.

9. High qualty quartz sand flter, can remove the large impuitis, alga and so on, can opfional manual1

automafic control.

10. Cartidge filer prolect RO membrane, prolong RO membrane's service lie.

11. High qulity rawwater pump and high pressure pump forseawater desalination.

12. Final Production water of utrviolet disinfection online to ensure the output water qulily.

13. High qulity SS316L electic slowly open valve, slow opening andclosing device high pressure.

14. Simple connection, safe and rliable.

15. Alof the high pressure ftings adopt Ss3 16 matenial, safe and corsionoesisant.

16. Low pressure ffings adopt high quality UVPC maternial, Food grade health.

17.Automatic and regular washing can improve weter qulity and water quanfty and efetcfvely prolong

the servioe ife of RO memtbrane.

18. DC24V direcet crrent is used for control and instrument, which is safe and rliable.

Machine Maintenance Tips

Consumable replacement cycle:

1. Quartz sand: about one year, depends on water quality.

2. 5 micron PP filter : about 3 months, depends on wator quality.

3. RO membrane: about 3 years , depends on water quality.

Note: the above re placement cycle is calculated by running 20 hours per day on the premise of meeting the conditions of use and maintenance of the equi pment.

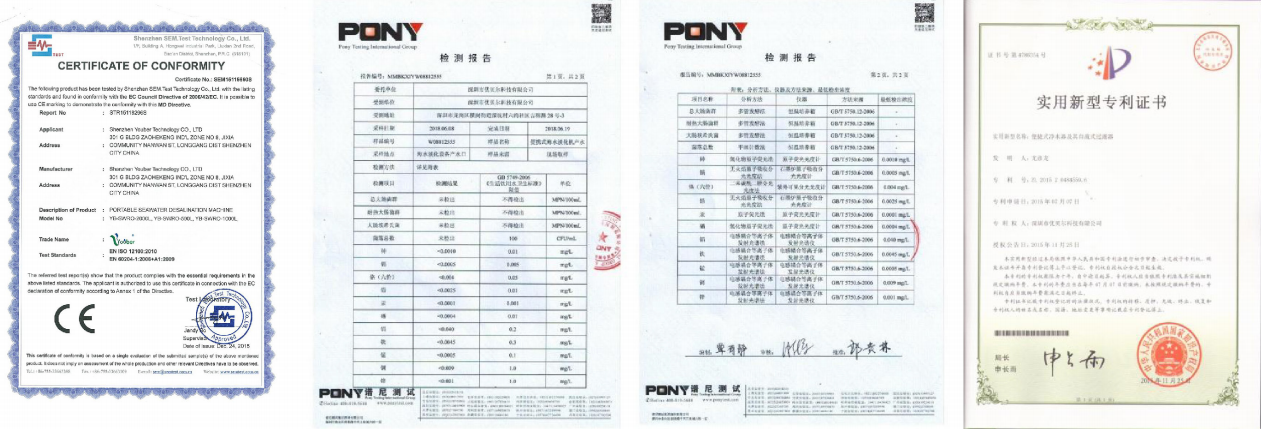

Certificates of Suppliers

English

English